Entering a copper mine deep inside a mountain was one of the more awesome things we did on our trip to Arizona. Gathering inside the main building at the Bisbee Copper Queen Mine, we explored the rocks for sale inside the gift shop until our group was called.

We were each given a brass tag with a number, like a real miner. These would survive in case of an explosion or cave-in to identify the bodies. This was called “brassing in” when miners reported for duty. At the end of his shift, the miner would turn his tag back in to the timekeeper. Here’s a replica from the Bisbee historical museum of the timekeeper’s station.

Then we each went along an assembly line to get outfitted. With assistance from a seasoned miner, we donned yellow slickers, lights around our necks, belts and helmets. From here, we boarded a tram for our ride into the mountain. We sat astride like on a horse. A bell clanged, and the tram jerked forward. A gap yawned in front of us as we moved ahead. Wheels creaked as we entered a dark tunnel with chiseled rock walls.

We glimpsed other passages leading off into pitch blackness as we rattled deeper into the interior. Rocks glistened in places from crystals. Dust-covered ore carts and discarded tools lay about. The only way we could see in the dark was with our lights. Wood supports shored up the walls at intervals. Loose rock was “barred” or secured behind metal bars.

This mine, unlike others, was cool with a temperature in the fifties. That’s because air flows in from outside. We rode horizontally into the mountain. Other mines go straight down. Those mines are hotter and need air pumped in. This one evolved from a natural hole and was discovered by army scouts in 1877. Because methane gas wasn’t a danger here, miners could smoke in these tunnels. However, the men had to hand roll their cigarettes so they would go out if dropped.

Riding on the tram, I felt someone tap my head. I twisted around. My husband hadn’t done it. Who, then? A ghost? Mines were rife with accidents: explosions, cave-ins, tumbles down the shaft, falling rock. Who knew how many workers had died there? Unexpectedly, lots of orbs showed on some of my photos. Spiritual entities or dust motes? More scenes from the museum.

Eventually we came to a stop and got off at a big dug-out chamber where our guide explained about mining methods. Miners worked by candlelight and swung a pickax to break off rock from the walls. If the rock was too hard, they drilled holes in the rock using a steel drill bit and a sledgehammer. They’d put in a stick of dynamite and light the fuse. This broke up the rock and expanded the tunnel. They’d transport the ore to chutes. It went down into ore carts which were pulled by mules. The mules lived in the mines. When their time was up, they were taken to the surface with blinders on and their vision gradually restored so they didn’t go blind from the brightness.

We saw the metal toilets where early miners did their business as they toiled for 12 hour shifts underground. Those seats must have been chilly!

If a miner needed to reach the surface, he’d tug a rope pull by a cage. The cage operator would send down the open wood platform. We saw the boss’s tricycle (or similar conveyance) by which he checked on his men twice a day.

They pumped in air and water. The water cut down on dust, which could damage the lungs. The compressed air was used in machinery-operated drills once they became available. Today, the mines are tested for radon gas. Other types of mines have to be tested for air and methane gas. You can light a candle to see if there’s air flow. Parakeets were used to detect dangerous gases. Miners would equip themselves with a helmet, candles and matches, lunch pail, and sometimes a survival kit or gas mask.

Copper doesn’t deposit in veins like gold. It’s mixed in the ore, so processing techniques are needed to separate it from other substances. It would have been sent to a stamp mill for crushing and refining. Side products could be gold, silver, zinc, lead, and other minerals.

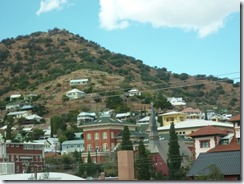

I learned a lot more when we went to the history museum in Bisbee, after a pleasant lunch in town. Bisbee is built among the hills and has some interesting shops and restaurants as well as a historic hotel.

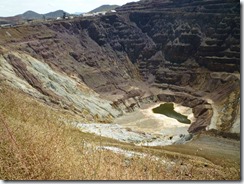

I won’t bore you with further details about mining, but they were fascinating. The method used today is called the open pit technique. You can see the results at the Lavender Pit. It’s not a pretty sight.

Disclaimer: Any inaccuracies are due to my note taking and not the information presented.

You can see more photos here: http://fw.to/SB2DmEH

<><><>

How does this relate to my story? In Peril by Ponytail, Marla and Dalton are staying at an Arizona dude ranch owned by his uncle. Raymond is also renovating a ghost town that used to be a former copper mining camp. Marla’s exploration of a hillside where a worker vanished leads to an astounding discovery. Consider the information above and use your imagination to determine where Marla and Dalton find themselves next.

It really is sickening to see the resulting damage to the earth from mining. Just watched a special on TV about the lead in the left over gravel being so dangerous to children.

One question. I thought they used canaries??

You might be right about canaries. The miner I interviewed said parakeets. I should look it up. And yes, it’s sad how the open pit mining destroys the beautiful landscape.

An interesting account, Nancy. I can see a trade-off between sending men and mules into those scary mines and the new procedure that scars the land. Sounds like you have wonderful material for your story. Knowing Marla, her time underground won’t be uneventful

Yes, it’s great material. Mules were deployed before the days of locomotives that could haul the ore carts. Also, I believe the miner said that the quality of the copper is better from deeper underground than from the open pit technique.

I just have to add that pit mining does not leave the land in that ugly state. As the ore is exhausted, the land is reclaimed and returned to its natural state. You could have seen this at the Pima Mine site.

The Rosemont Mine (http://rosemontcopper.com) has experienced interminable delays in opening because of the need to satisfy environmental requirements and the objections of latecomers to the state who think all it is is a place to retire.

If you want electric wires, pipes, and all the other things made out of copper, it has to come from somewhere. Arizona’s economy was founded on the 5 Cs. Number one is Copper. I’m far from in favor of raping the land, but our natural resources need to be developed and mining is a huge source of jobs–jobs that are desperately needed in our weak economy.

The only open pit I saw was the Lavender Mine, and that had not been filled in. Someone said there was talk of reopening it, because as you say, copper is a valuable resource. Mining methods are always controversial.